Fabrication at the Molecular Level

This event has passed

Livestream via Zoom

April 21, 2020

4pm

Hear about the latest research in digital fabrication at nanoscale from UW researchers in NanoES, Bio-Engineering, and Chemistry. Researchers will share lightning talks of their work and answer questions in a livestream open to all of UW.

The Lineup

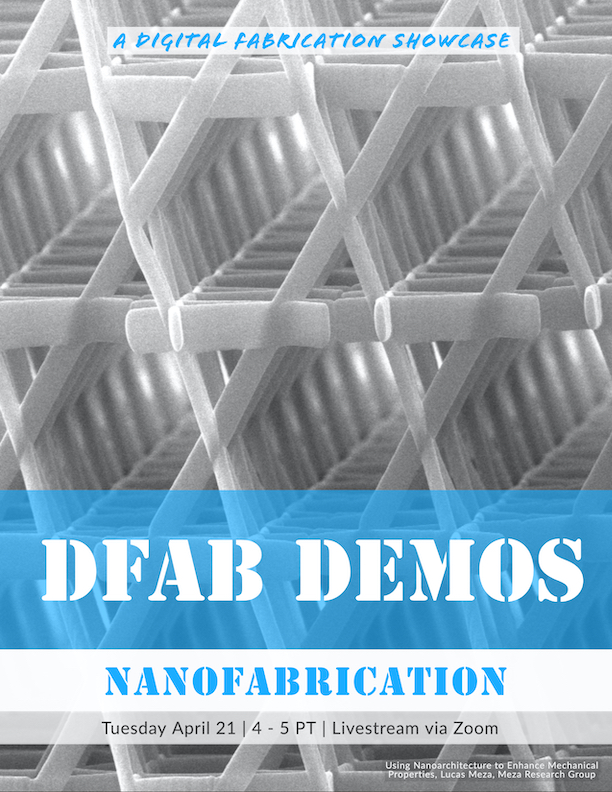

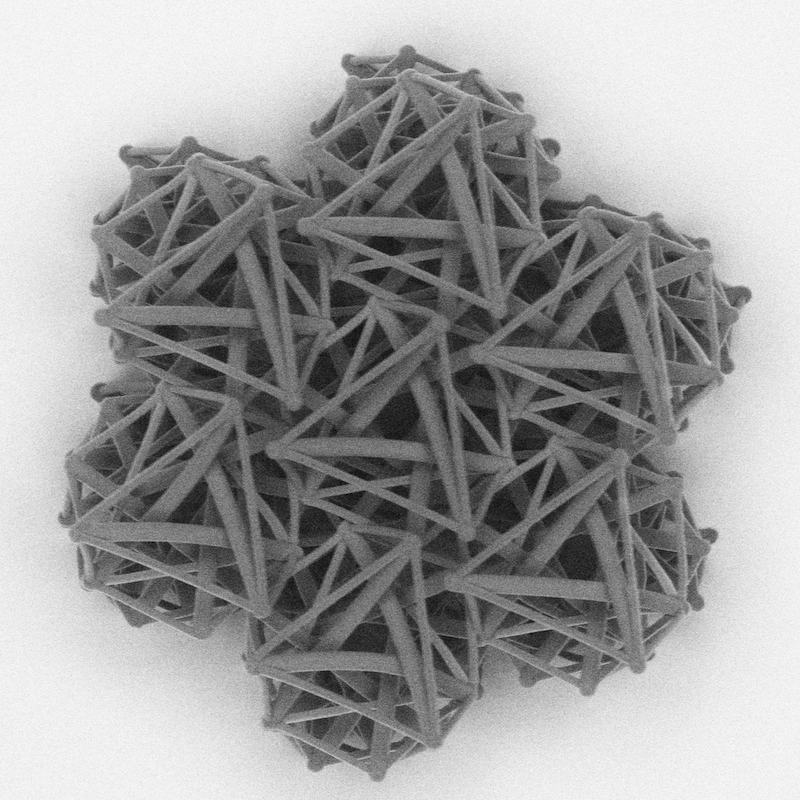

Nanomaterials and Nanoscale Additive Manufacturing

Lucas Meza (MechE)

Nanomaterials have exceptional properties — such as ultrahigh strength and toughness, damage tolerance, and enhanced ductility — but these are lost in traditional engineering materials. Meza’s group uses nanoscale additive manufacturing (AM) in combination with advanced materials processing techniques and in-situ nanomechanical testing to create new materials from the nanoscale up then break them down to study their mechanical properties across length scales starting at the nanometer level.

Learn more

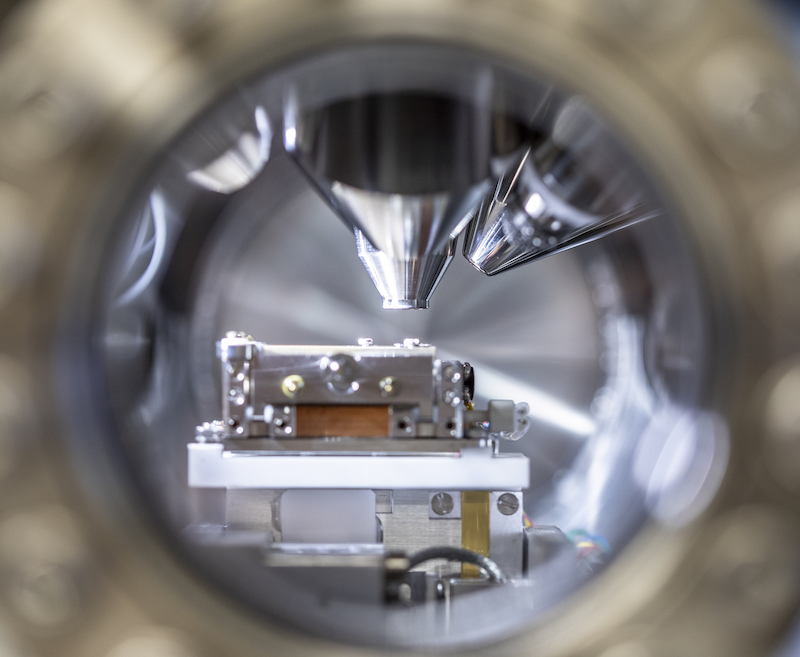

A Look Inside the Molecular Analysis Facility

Micah Glaz (MAF), Lara Gamble (BioE)

The Molecular Analysis Facility (MAF) has a suite of characterization tools for studying fabricated devices. The MAF is an NSF NNCI funded user facility located on the ground floor of the Molecular Engineering and Sciences (MolES) building. This presentation will include a brief overview of tools available at the MAF including SEM, TEM, AFM, XPS, as well as an example of device characterization.

Learn more

Innovations in Miniature Lenses

Zheyi Han, Karl Bohringer (BioeE and ECE)

Miniature lenses with tunable focus are essential components for many modern applications involving compact optical systems. By integrating metasurface optics with electrostatic microelectromechanical systems (MEMS) based on the Alvarez lens design, we have demonstrated a varifocal miniature lens capable of producing fast and controllable optical change with low power.

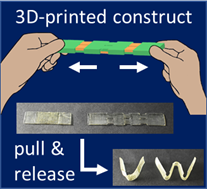

4D Printing with Polymeric Ion Gels

Alshakim Nelson (Chemistry)

4D printing is the process of creating 3D printed structures that undergo a shape transformation in response to an external stimulus. Using mechano-activation to induce shape change offers advantages such as orthogonality to other stimuli and facile control over magnitude of the applied loads. Herein, we will discuss mechanically activated morphing with full programmability and directional control of objects that were 3D printed from polymeric ion gels.